SSMMS Non-woven Fabrics Industry Knowledge

What are the key advantages of SSMMS non-woven fabrics in medical and hygiene applications, and how do the special treatments of hydrophilic and super-soft enhance their performance?

SSMMS non-woven fabrics have gained significant recognition in the medical and hygiene industries due to their exceptional properties and versatile applications. Let's explore the key advantages of SSMMS non-woven fabrics and how the special treatments of hydrophilic and super-soft enhance their performance.

Advantages of SSMMS Non-Woven Fabrics in Medical and Hygiene Applications:

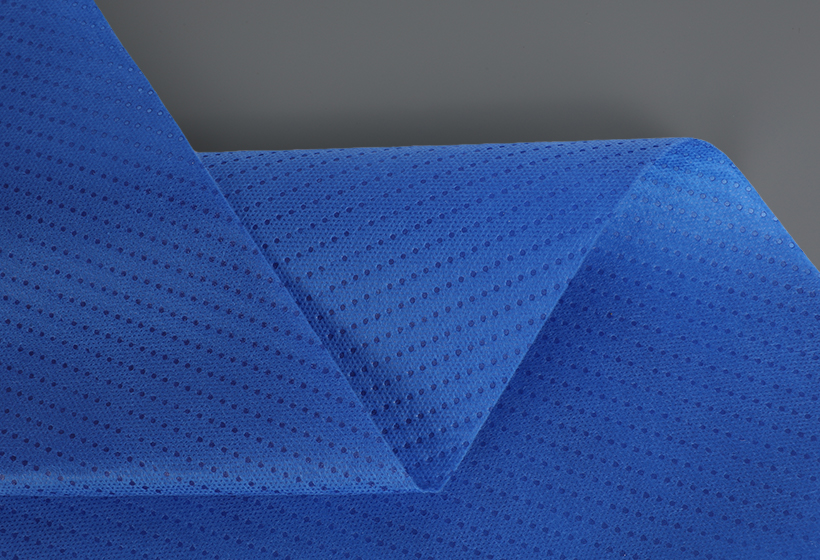

1. High Barrier Properties: SSMMS (Spunbond, Spunbond, Meltblown, Meltblown, Spunbond) non-woven fabrics are composed of multiple layers of spunbond and melt-blown fibers. This unique structure provides excellent barrier properties, effectively preventing the penetration of liquid, bacteria, and particles. It makes SSMMS non-woven fabrics ideal for medical applications where infection control and protection are crucial, such as surgical gowns, protective clothing, surgical drapes, and surgical kits.

2. Breathability and Comfort: Despite their high barrier properties, SSMMS non-woven fabrics offer excellent breathability. The spunbond layers in the fabric allow air and moisture vapor to pass through, enhancing comfort for the wearer. This is particularly important in medical and hygiene applications where prolonged use is common. The breathable nature of SSMMS non-woven fabrics helps reduce heat buildup and moisture retention, minimizing discomfort and promoting a better user experience.

3. Softness and Skin-Friendliness: SSMMS non-woven fabrics are designed to be gentle on the skin. The fibers used in the fabric are engineered to be fine and soft, ensuring a smooth and non-irritating surface. This makes them suitable for applications such as baby diapers, sanitary napkins, and adult diapers, where comfort and skin-friendliness are essential. The softness of SSMMS non-woven fabrics helps prevent skin chafing, redness, and irritation, promoting better skin health and overall user comfort.

Special Treatments of Hydrophilic and Super-Soft:

1. Hydrophilic Treatment: SSMMS non-woven fabrics can undergo a hydrophilic treatment, which enhances their ability to absorb and distribute liquids. The hydrophilic treatment modifies the fabric's surface, allowing it to attract and spread liquid quickly, improving its performance in medical and hygiene applications. In surgical drapes, for example, the hydrophilic treatment helps prevent liquid pooling and promotes efficient absorption, maintaining a dry and sterile surgical environment.

2. Super-Soft Treatment: The super-soft treatment of SSMMS non-woven fabrics further enhances their tactile properties and overall comfort. The treatment involves adding specialized softening agents to the fabric, resulting in a luxurious and plush feel. The super-soft treatment makes the fabric exceptionally gentle on the skin, reducing friction and irritation. In applications like baby diapers or sanitary napkins, the super-soft treatment enhances the user's comfort and promotes a soft and pleasant wearing experience.

In conclusion, SSMMS non-woven fabrics offer significant advantages in medical and hygiene applications. Their high barrier properties, breathability, and softness make them ideal for surgical gowns, protective clothing, surgical drapes, baby diapers, sanitary napkins, and adult diapers. The special treatments of hydrophilic and super-soft further enhance the fabric's performance, improving liquid absorption, and ensuring a gentle and comfortable experience for the wearer. By utilizing SSMMS non-woven fabrics with these special treatments, manufacturers can provide high-quality products that meet the stringent requirements of the medical and hygiene industries.

What makes SSMMS non-woven fabrics stand out in terms of performance and reliability for medical and hygiene applications, and how does the customization of weight, width, and color cater to specific customer needs?

SSMMS non-woven fabrics have become a preferred choice in the medical and hygiene industries due to their outstanding performance and reliability. Let's explore what sets SSMMS non-woven fabrics apart and how the customization options of weight, width, and color cater to the specific needs of customers.

Performance and Reliability of SSMMS Non-Woven Fabrics in Medical and Hygiene Applications:

High Strength and Barrier Protection: SSMMS non-woven fabrics offer exceptional strength and barrier properties. The combination of multiple layers of spun-bond and melt-blown fibers creates a fabric with excellent tear resistance, durability, and a high barrier against liquids, bacteria, and particles. This ensures reliable protection in medical applications such as surgical gowns, protective clothing, surgical drapes, and surgical kits, where maintaining a sterile environment is critical.

Superior Absorbency and Fluid Management: SSMMS non-woven fabrics can be treated to have hydrophilic properties, enabling efficient absorption and distribution of liquids. This feature is especially valuable in medical and hygiene applications where rapid fluid absorption is essential, such as in surgical drapes or hygiene products like baby diapers, sanitary napkins, and adult diapers. The fabrics' ability to effectively manage fluids helps maintain dryness, comfort, and hygiene.

Breathability and Comfort: Despite their barrier properties, SSMMS non-woven fabrics are designed to be breathable, allowing air and moisture vapor to pass through. This breathability ensures comfort and helps regulate body temperature, making them suitable for extended wear. The fabrics' softness and gentle texture contribute to a comfortable experience, reducing friction and irritation on the skin.

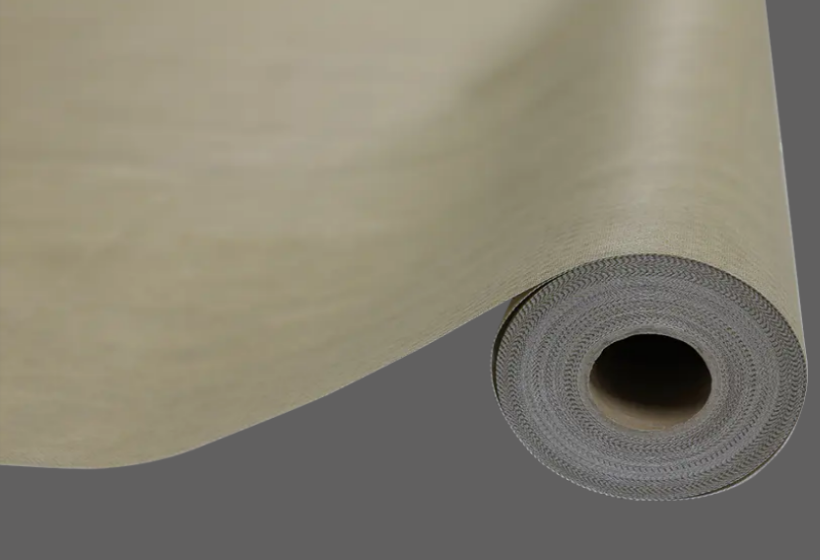

Customizable Weight, Width, and Color: SSMMS non-woven fabrics offer customization options in terms of weight, width, and color, allowing customers to meet their specific requirements. The weight of the fabric can be tailored within the range of 10gsm to 100gsm, enabling manufacturers to select the optimal thickness for their applications. The maximum width of 3.2 meters provides flexibility in production processes and allows for efficient utilization of materials. Furthermore, the availability of customizable colors ensures that customers can achieve their desired aesthetics and branding.

The customization of weight, width, and color in SSMMS non-woven fabrics caters to the specific needs of customers in several ways:

Application-Specific Requirements: Different medical and hygiene applications may demand specific fabric weights to achieve the desired performance and functionality. Customizing the weight allows manufacturers to tailor the fabric to meet the requirements of surgical gowns, protective clothing, baby diapers, sanitary napkins, or other applications.

Efficiency in Production: Customizable width options facilitate efficient production processes, enabling manufacturers to optimize material utilization and minimize waste. The ability to manufacture wider fabrics can also lead to enhanced productivity and cost-effectiveness in large-scale production.

Branding and Aesthetics: Customizable color options provide manufacturers the opportunity to align the fabric with their brand identity or meet specific design preferences. This allows for differentiation and customization of products, contributing to brand recognition and customer appeal.

In summary, SSMMS non-woven fabrics offer exceptional performance and reliability in medical and hygiene applications. Their high strength, barrier protection, absorbency, breathability, and comfort make them ideal for surgical gowns, protective clothing, surgical drapes, baby diapers, sanitary napkins, and adult diapers. Additionally, the customization options of weight, width, and color enable manufacturers to tailor the fabric to specific application requirements and branding needs, ensuring customer satisfaction and product differentiation.

English

English Español

Español

Innovation Team

Innovation Team Patented Technology

Patented Technology Quality Assurance

Quality Assurance Efficient Response

Efficient Response