Fully Degradable PLA Polylactic acid Industry Knowledge

How do fully degradable PLA polylactic nonwoven fabrics contribute to sustainable and eco-friendly solutions in various industries, and what are their key advantages over conventional nonwoven materials?

Fully degradable PLA (Polylactic Acid) polylactic nonwoven fabrics have emerged as an innovative and sustainable alternative to conventional nonwoven materials. These fabrics are derived from renewable resources such as corn starch or sugarcane, making them environmentally friendly and biodegradable. Let's explore how fully degradable PLA polylactic nonwoven fabrics contribute to sustainable solutions across industries and discuss their key advantages over conventional nonwoven materials.

One of the most significant contributions of fully degradable PLA polylactic nonwoven fabrics is their positive environmental impact. Being derived from renewable resources, these fabrics have a significantly lower carbon footprint compared to nonwovens made from fossil fuel-based materials. The production of PLA polylactic nonwovens consumes less energy and generates fewer greenhouse gas emissions, thereby mitigating the impact on climate change.

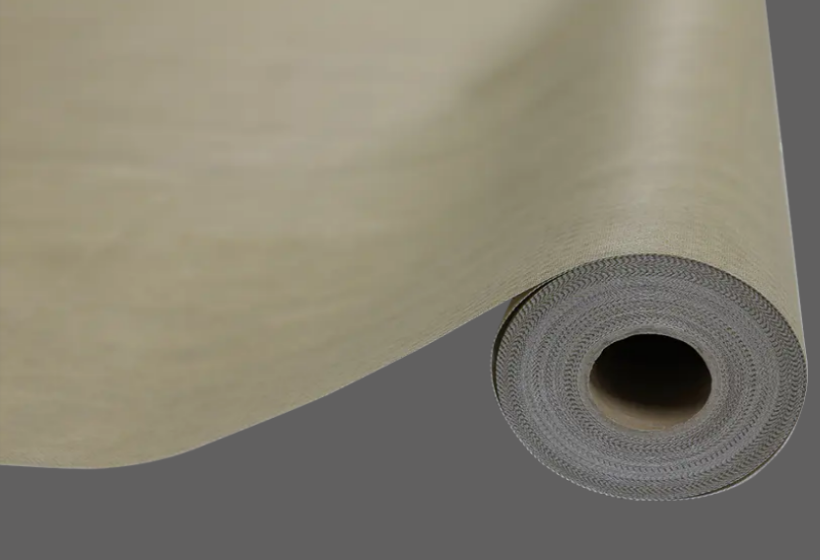

The biodegradability of PLA polylactic nonwoven fabrics is another crucial factor in their sustainability. These fabrics are designed to break down naturally over time, typically through composting or other suitable degradation processes. This characteristic ensures that at the end of their lifecycle, they do not contribute to landfill waste and can be effectively managed through environmentally friendly disposal methods. By choosing fully degradable PLA polylactic nonwoven fabrics, industries can significantly reduce their environmental footprint and support the transition towards a circular economy.

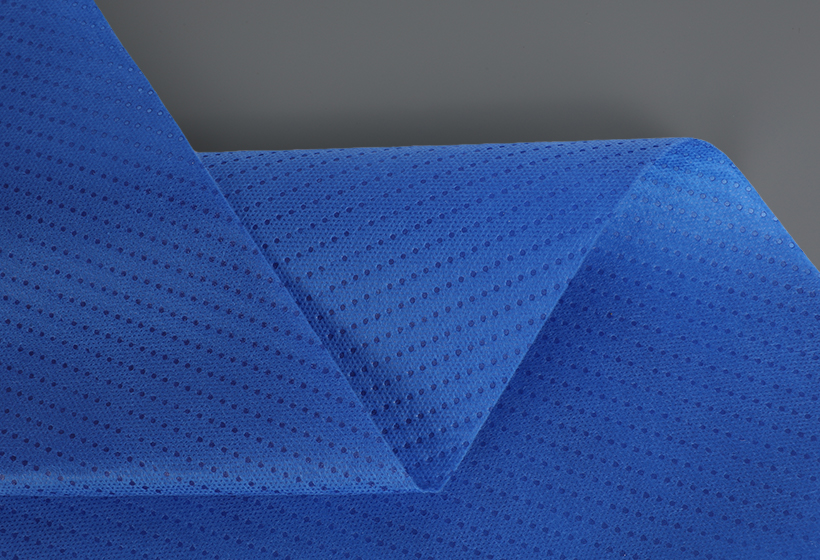

In addition to their environmental benefits, fully degradable PLA polylactic nonwoven fabrics offer several advantages over conventional nonwoven materials. One of the key advantages is their versatility. These fabrics can be produced in a wide range of weights, ranging from 10gsm to 200gsm, providing flexibility to meet various application requirements. The fabric width of 1.6m allows for efficient manufacturing processes and enables seamless integration into different products and designs.

Fully degradable PLA polylactic nonwoven fabrics exhibit excellent strength and durability, despite their biodegradable nature. They offer reliable performance in perse applications, including hygiene products, medical supplies, packaging, agriculture, and more. The fabrics maintain their structural integrity throughout their intended use, providing the necessary functionality and ensuring optimal performance.

Furthermore, fully degradable PLA polylactic nonwoven fabrics are hypoallergenic and free from harmful substances. They are suitable for applications where human contact is involved, such as in hygiene products or medical supplies. The fabric's soft texture and breathable nature make it comfortable to use, promoting user satisfaction and well-being.

The white color option of fully degradable PLA polylactic nonwoven fabrics offers a clean and aesthetically pleasing appearance. It allows for consistency in product design and branding, enhancing the overall visual appeal.

The customizable nature of PLA polylactic nonwoven fabrics enables manufacturers to tailor the material to specific application requirements. It can be easily combined with other materials or treated with additional coatings to enhance properties such as water resistance, flame retardancy, or antimicrobial characteristics. This adaptability ensures that the fabric can meet the perse needs of different industries and applications.

In conclusion, fully degradable PLA polylactic nonwoven fabrics provide sustainable and eco-friendly solutions across industries. Their renewable origin, biodegradability, and lower carbon footprint contribute to environmental conservation and support the transition to a circular economy. The fabrics' versatility, strength, hypoallergenic nature, and customizable features make them a viable alternative to conventional nonwoven materials. By adopting fully degradable PLA polylactic nonwoven fabrics, manufacturers can align their products with sustainable practices and meet the growing demand for environmentally friendly solutions.

What are the key applications and advantages of Fully Degradable PLA Polylactic Nonwoven Fabrics in various industries?

Fully Degradable PLA Polylactic Nonwoven Fabrics have gained significant attention in recent years as a sustainable and versatile textile solution. With their unique properties and eco-friendly nature, these fabrics have found applications across various industries. In this article, we will explore the key applications and advantages of Fully Degradable PLA Polylactic Nonwoven Fabrics, highlighting their role in driving sustainability and innovation.

1. Hygiene and Personal Care Industry: Fully Degradable PLA Polylactic Nonwoven Fabrics have found extensive use in the hygiene and personal care industry. They are utilized in products such as diapers, feminine hygiene products, and wet wipes. The soft and non-irritating nature of PLA nonwoven fabrics makes them ideal for sensitive skin. Additionally, their high liquid absorption capacity and breathability contribute to enhanced comfort and performance in hygiene applications.

2. Medical and Healthcare Industry: The medical and healthcare sector has recognized the benefits of Fully Degradable PLA Polylactic Nonwoven Fabrics. These fabrics are widely used in medical masks, surgical gowns, wound dressings, and other disposable medical products. PLA nonwoven fabrics offer excellent barrier properties, ensuring protection against microorganisms. Their biodegradability also reduces the environmental impact associated with medical waste disposal.

3. Agriculture and Horticulture: Fully Degradable PLA Polylactic Nonwoven Fabrics have found applications in agriculture and horticulture. They are used as groundcovers, mulching films, and crop covers. These fabrics provide protection against weeds, help retain soil moisture, and promote optimal growing conditions. Their biodegradability allows them to naturally degrade in the soil after use, minimizing the need for manual removal.

4. Packaging Industry: PLA nonwoven fabrics are increasingly being used in the packaging industry as an eco-friendly alternative to traditional packaging materials. They can be used as cushioning materials, protective wraps, and bags. PLA nonwoven fabrics offer good tensile strength and tear resistance, ensuring reliable packaging solutions. Their biodegradability aligns with the growing demand for sustainable packaging options.

5. Filtration and Separation: Fully Degradable PLA Polylactic Nonwoven Fabrics find applications in the filtration and separation industry. They are utilized in air filters, liquid filters, and oil-absorbent products. PLA nonwoven fabrics exhibit high porosity and can be engineered to have specific filtration properties. Their renewable and biodegradable nature contributes to sustainable filtration solutions.

The advantages of Fully Degradable PLA Polylactic Nonwoven Fabrics extend beyond their specific applications. Some key benefits include:

1. Sustainability: PLA nonwoven fabrics are derived from renewable resources and are fully biodegradable. They offer a sustainable alternative to conventional nonwoven fabrics, which are often made from non-renewable fossil fuels and contribute to environmental pollution.

2. Reduced Environmental Impact: PLA nonwoven fabrics have a lower carbon footprint compared to synthetic nonwoven fabrics. Their production requires less energy and generates fewer greenhouse gas emissions. Moreover, their biodegradability ensures minimal environmental impact at the end of their lifecycle.

3. Versatility: Fully Degradable PLA Polylactic Nonwoven Fabrics can be engineered to possess a wide range of properties, such as different weights, textures, and porosities. This versatility enables their application in perse industries, catering to specific needs and requirements.

4. Biocompatibility: PLA nonwoven fabrics are biocompatible, making them suitable for various medical and healthcare applications. They are non-toxic, non-allergenic, and do not cause skin irritation.

English

English Español

Español

Innovation Team

Innovation Team Patented Technology

Patented Technology Quality Assurance

Quality Assurance Efficient Response

Efficient Response