Bicomponent fibers are composed of two different components that lie side by side. These fibers may not be separated later. The two components must show good adhesion to form a stable bond. Otherwise, the fibers will be separated, which may lead to insufficient adhesion and inability to withstand excessive mechanical forces. Listed below are some uses for these fibers. If you're interested in learning more, you can check out this article!

Bicomponent fibers are generally made from two distinct polymers. They are produced using a melt spinning system and are formed by simultaneously spinning two fiber components. Both polymers can be of different chemical compositions and degrees of crystallization, which can result in differential expansion and shrinkage. These fibers also have different patterns and configurations. The cross-section of bicomponent fibers depends on several factors, including the polymer distribution, metering, and viscosity.

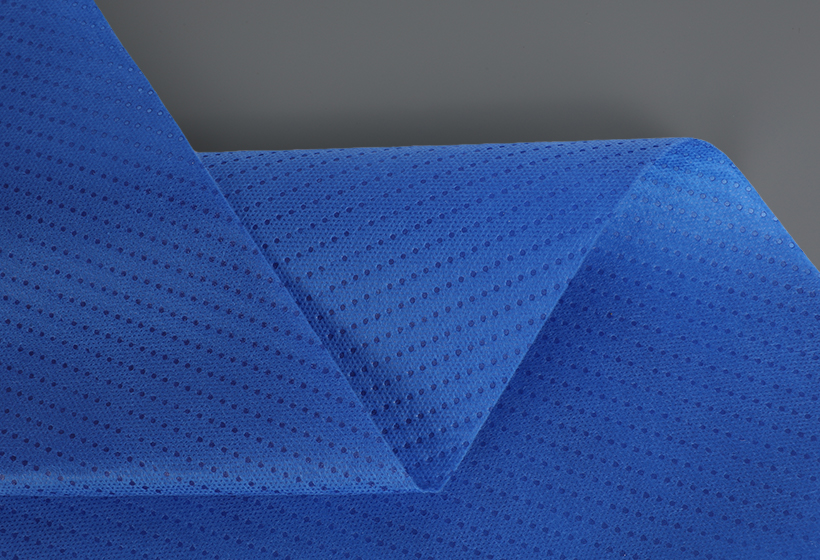

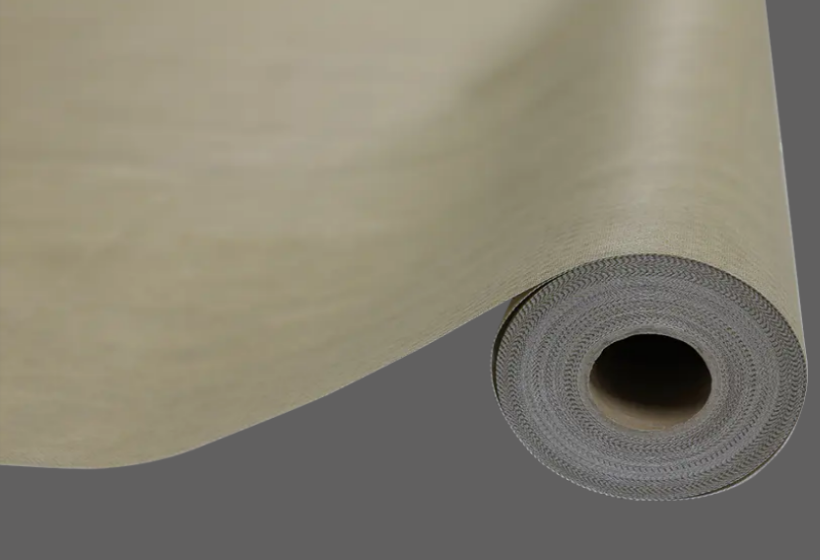

The different cross-sections of bicomponent fibers allow them to be used for many applications. These fibers can be segmented pie, core-sheath, side-by-side, or islands-in-the-sea. These fibers can be used in various applications, including advanced textiles, bulky goods, and microfiber fabrics. Many companies produce different types of commercial bicomponent fibers.

When determining the physical structure of bicomponent fibers, scientists can identify the chemical components through a variety of methods, including the use of microscopic observations. FTIR spectra and EDS analysis provide the most convenient means of determining the two components. However, no single method is sufficient to determine the properties of bicomponent fibers. Therefore, a combination of several techniques is required to determine their composition.

Bicomponent fibers can be produced by spinning two different polymers into two separate spinning channels. This can be done in melt or solution. Different spinneret shapes are used to prepare these fibers. Preparation methods for bicomponent fibers include electrospinning, melt-blowing, gel spinning, and spun bonding. Bicomponent fibers are often referred to as conjugated fibers.

The combination of core material and shell material offers multiple advantages. Compared to monocomponent fibers, bicomponent fibers have superior mechanical properties, increased strength, and improved spinnability. These fibers have multiple uses and are expected to continue revolutionizing the textile industry. One of the most important applications of bicomponent fibers is nonwovens. With rapid nonwoven technology, there's a huge market for soft nonwoven fabrics. Bicomponent fibers are on the forefront of meeting this demand.

English

English Español

Español