As an important nonwoven material, the diversification of raw materials of meltblown nonwovens not only enriches the performance and application fields of products, but also promotes the sustainable development of the industry. In recent years, with the improvement of environmental awareness and the popularization of the concept of sustainable development, the application of environmentally friendly materials in the field of meltblown nonwovens has gradually become a new favorite.

1. Coexistence of traditional raw materials and emerging materials

The traditional raw materials of meltblown nonwovens mainly include thermoplastic polymers such as polypropylene (PP). These materials have excellent physical properties and processing properties, can meet the needs of meltblown technology, and produce nonwoven products with stable performance. However, with the advancement of science and technology and the improvement of environmental protection requirements, emerging materials have begun to emerge.

2. The rise of environmentally friendly materials

Bio-based materials: biodegradable materials such as polylactic acid (PLA), which are derived from renewable resources such as corn starch, sugarcane, etc., can be decomposed in the natural environment and reduce the impact on the environment. PLA nonwovens not only have the excellent properties of traditional nonwovens, but also have degradability, and are an important representative of environmentally friendly materials.

Recycled materials: The use of recycled materials such as waste plastics to produce meltblown nonwovens not only reduces dependence on primary resources, but also reduces the generation of waste. This practice is in line with the concept of circular economy and helps to maximize the use of resources.

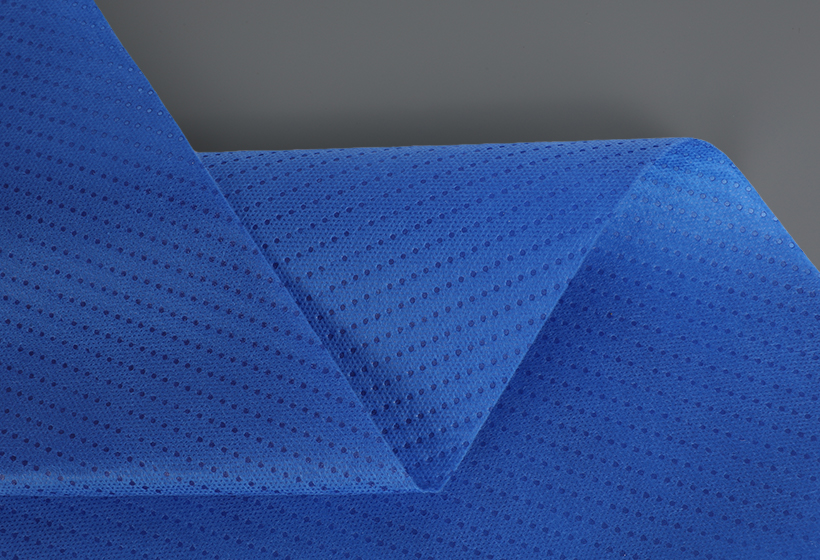

Special functional materials: In order to meet the needs of specific fields, some materials with special functions are also used in the production of meltblown nonwovens. For example, antibacterial materials, waterproof and breathable materials, etc., these materials can give meltblown nonwovens more performance advantages and broaden their application areas.

3. Application advantages of environmentally friendly materials

Environmentally friendly: The use of environmentally friendly materials reduces the generation of waste and environmental pollution, which is in line with global environmental trends and sustainable development requirements.

Superior performance: Some environmentally friendly materials not only maintain or even improve the performance of traditional nonwovens, but also have some new functional characteristics, such as degradability and antibacterial properties.

Market demand growth: As consumers' recognition of environmentally friendly products increases, the market demand for meltblown nonwovens made of environmentally friendly materials continues to grow, bringing new development opportunities to the industry.

4. Industry trends and prospects

In the future, the meltblown nonwoven industry will continue to develop in the direction of raw material diversification and environmental protection. On the one hand, with the continuous advancement of technology and the emergence of new materials, the raw material selection of meltblown nonwovens will be more extensive; on the other hand, with the popularization of environmental awareness and the increase in consumer demand for environmentally friendly products, environmentally friendly materials will become an important development direction in the field of meltblown nonwovens. At the same time, the industry will also strengthen technological innovation and product research and development to promote the application and popularization of meltblown nonwovens in more fields.

English

English Español

Español