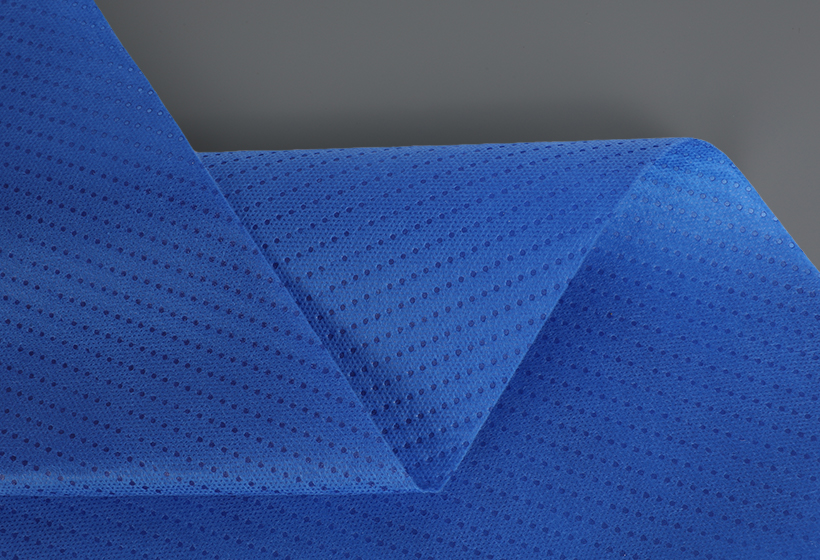

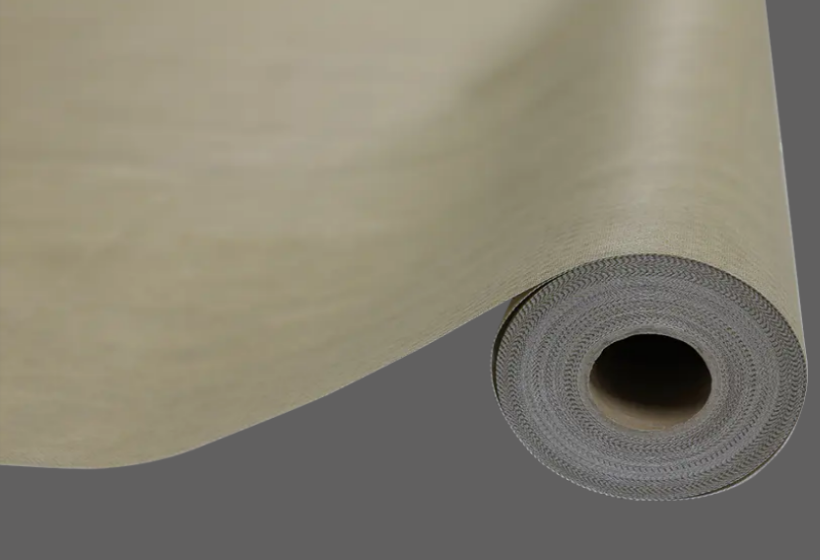

SF, SFS, FSF laminated nonwoven fabric is a new composite material that combines multi-layer structure with nonwoven fabric technology. By laminating different fiber materials layer by layer and combining different functional membranes (such as breathable membrane, water-blocking membrane, etc.), these materials can provide more excellent performance:

Breathability and waterproofness: This laminated structure can achieve a balance between breathability and waterproofness, and is widely used in protective clothing, medical equipment, outdoor products and other fields. The optional breathable membrane allows this material to ensure waterproof function while effectively avoiding the discomfort caused by moisture accumulation to the wearer.

Lightweight design: The structure of nonwoven fabric makes the material lighter and suitable for application scenarios that need to reduce weight without sacrificing performance. For example, protective clothing in sports, outdoor activities and other fields often uses this type of material to improve wearing comfort and movement flexibility.

Environmental protection: As a nonwoven material, SF, SFS and FSF laminated nonwoven fabrics not only have excellent mechanical properties, but also have high degradability, which meets the requirements of modern society for environmental protection. The production process usually used by non-woven materials is also relatively low-energy, which is in line with the concept of green environmental protection.

Innovative application of optional breathable membrane

The optional breathable membrane is a highlight of these laminated non-woven fabrics. The main function of the breathable membrane is to allow tiny molecules such as gas and water vapor to penetrate, while blocking the penetration of liquids such as water droplets. Therefore, SF, SFS, and FSF laminated non-woven fabrics with breathable membranes are widely used in occasions that require perspiration and breathability, such as:

Protective clothing: Especially in epidemic prevention and control or high-risk environments, breathable membrane laminated non-woven fabrics can provide higher comfort and protection, ensuring that protective clothing can effectively isolate viruses or pollutants, while allowing the wearer to maintain relatively comfortable breathability.

Medical field: For example, disposable medical protective equipment, surgical gowns, etc., they need to meet waterproof protection while avoiding excessive moisture. The addition of breathable membranes enables these medical supplies to achieve higher wearing comfort and functionality.

Outdoor products: such as tents, raincoats, backpacks, etc., breathable film laminated non-woven fabrics can provide ideal waterproof performance while preventing the inside from becoming soaked due to the inability to discharge sweat, ensuring comfort for long-term use.

English

English Español

Español