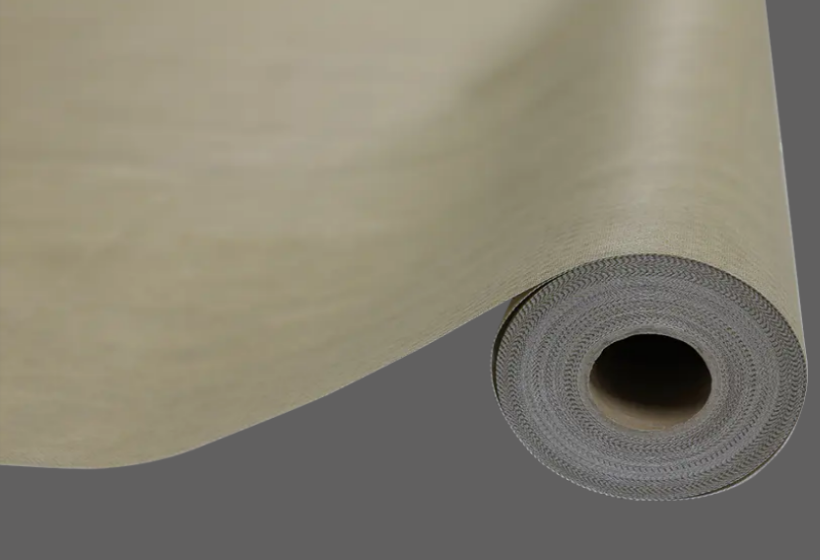

Mechanical properties

The mechanical properties of PET/PE bicomponent spunbond nonwovens are an important indicator for its industrial applications. Due to the combination of PET (polyethylene terephthalate) and PE (polyethylene), it can provide strong tensile strength and tear resistance. These properties make this type of nonwoven fabric used in high-intensity environments, such as filtration, protective materials and isolation layers. The study can analyze the effects of different ratios and spinning processes on its mechanical properties.

Chemical and heat resistance

PET/PE bicomponent nonwovens have good chemical resistance and can be used in environments with contact with chemicals such as acids, alkalis and solvents. In addition, the heat resistance of PE and the high melting point of PET enable this nonwoven to maintain good structural stability at higher temperatures. In view of the demand for high temperature and chemical corrosion resistant materials in industrial environments, its practical application in the chemical, automotive and construction industries can be explored.

UV resistance

The UV resistance of PET/PE nonwovens enables it to be used for a long time in outdoor environments without being easily degraded by UV radiation. By adjusting the ratio of PET and PE and post-treatment technology (such as anti-UV coating), its stability under long-term exposure to sunlight can be further improved. Application examples include geotextiles, building protection films, and agricultural shade nets.

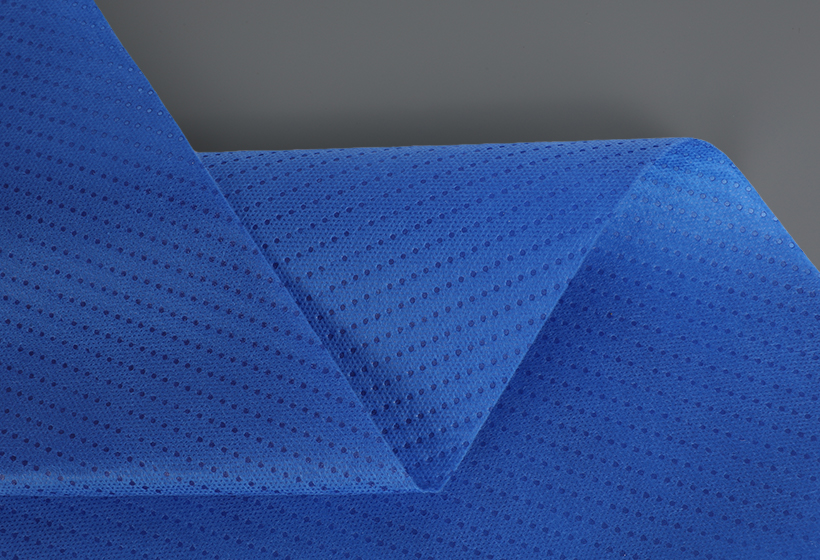

Water absorption and air permeability

Although PET and PE materials have low water absorption, a certain degree of air permeability and moderate water absorption can be achieved through the optimization of the spunbond process, making them suitable for some specific industrial needs, such as filter materials and sanitary products. Optimizing its moisture absorption and air permeability will help improve its application value in the field of environmental protection.

Durability and life cycle assessment

In industrial environments, the durability of a product directly affects its economic and environmental impact. By conducting long-term aging tests on the durability of PET/PE bicomponent nonwovens and analyzing its performance changes under exposure to factors such as humidity, temperature, and mechanical loads, its life cycle can be better evaluated, especially its potential in the fields of sustainable development and environmental protection.

English

English Español

Español