In the field of automobile manufacturing, how does the enhanced performance of Bi-component nonwoven fabric help PP Coarse Denier Nonwoven provide better support and stability in automobile interior materials, improving passenger comfort and safety?

In the field of automobile manufacturing, material selection has a crucial impact on the support, stability, comfort and safety of automobile interiors. Bi-component nonwoven fabric (bi-component nonwoven fabric) and PP Coarse Denier Nonwoven (polypropylene coarse denier nonwoven fabric) are two common materials, each with unique performance characteristics, and their combined use, especially in automobiles Among interior materials, it can significantly improve the overall performance of the product.

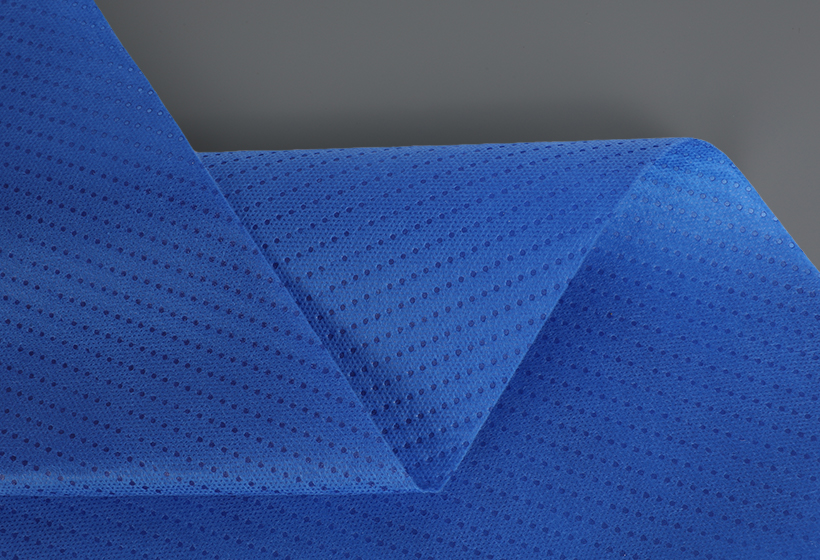

First of all, Bi-component nonwoven fabric is usually made of two fibers with different properties through special spinning technology. These fibers are structurally intertwined to form a unique three-dimensional network structure. This structure gives the bicomponent nonwoven fabric excellent mechanical properties and stability, allowing it to maintain good shape and dimensional stability when subjected to external forces.

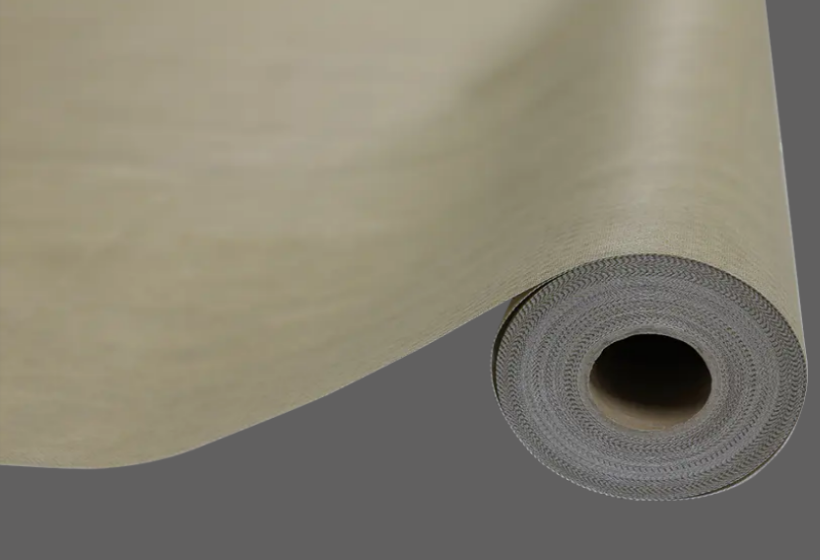

PP Coarse Denier Nonwoven, as a coarse-denier nonwoven fabric made of polypropylene fiber, has excellent wear resistance, impact resistance and good elasticity. This material is often used in automotive interiors for parts that need to withstand greater friction and impact, such as seats, door panels, etc.

When these two materials are combined, the enhanced properties of Bi-component nonwoven fabric can significantly improve the support and stability of PP Coarse Denier Nonwoven. Specifically, the three-dimensional network structure of the bicomponent nonwoven fabric provides a strong skeleton for the polypropylene coarse denier nonwoven fabric, allowing the entire material to maintain good shape and dimensional stability when subjected to external forces. This enhancement not only improves the durability and service life of automobile interior materials, but also effectively prevents the materials from deforming or loosening during use, thus ensuring the comfort and safety of passengers.

The enhanced properties of Bi-component nonwoven fabric can also improve the sound and thermal insulation properties of PP Coarse Denier Nonwoven. Because the fibers in the bicomponent nonwoven fabric are intertwined, a dense network structure is formed, which can effectively block the transmission of sound and heat. Therefore, using this combination of materials in car interiors can not only reduce the impact of noise and heat on passengers, but also improve the quietness and comfort of the car.

The enhanced properties of Bi-component nonwoven fabric play an important role in automotive interior materials. It can not only improve the support and stability of PP Coarse Denier Nonwoven, but also improve the sound and heat insulation properties of the material, thereby significantly improving passenger comfort and safety. Therefore, in the field of automobile manufacturing, this combined material has broad application prospects and market demand.

English

English Español

Español