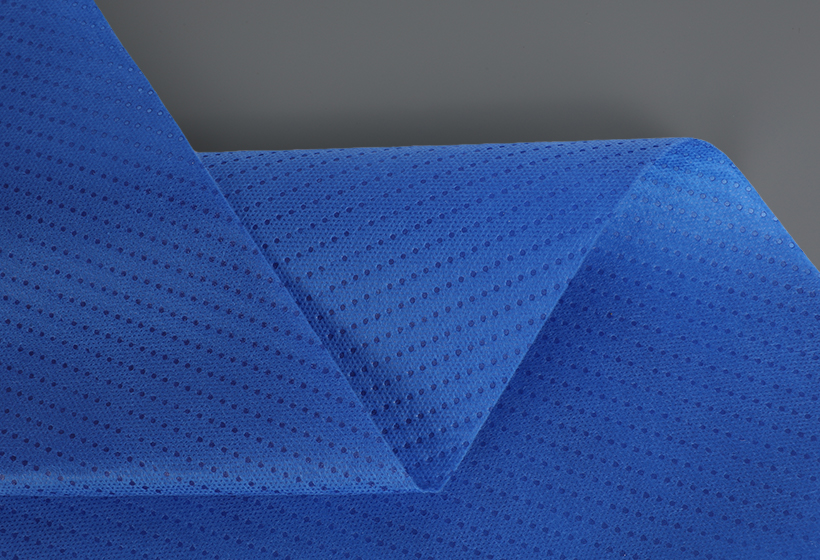

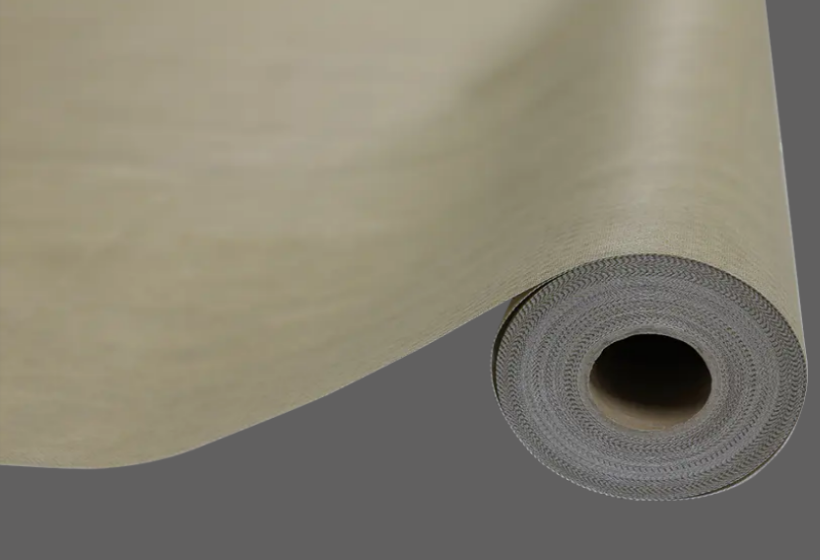

Filmed non-woven fabric breathability refers to the ability of a composite material composed of non-woven fabric and a thin film layer to allow the passage of air or moisture vapor while maintaining its barrier properties against liquids and contaminants. This property is essential in applications where comfort, moisture management, and air exchange are important considerations. Here are some key aspects of filmed non-woven fabric breathability:

Breathable Film Technology: Filmed non-woven fabric achieves breathability through the use of specially engineered breathable film technology. This film typically contains microperforations or pores that are too small to allow liquid water or contaminants to pass through but large enough to permit the movement of air and moisture vapor.

Moisture Vapor Transmission: The breathable film in the fabric allows moisture vapor from the wearer's body to escape through the material. This helps to regulate temperature and humidity, reducing the risk of discomfort and moisture buildup.

Comfort: Breathable filmed non-woven fabric enhances comfort in various applications, such as disposable diapers, adult incontinence products, disposable medical gowns, and wound dressings. The ability to breathe reduces the feeling of stickiness and dampness, making the product more comfortable for the user or patient.

Skin Health: In hygiene and medical applications, maintaining skin health is essential. Breathable materials help to reduce the risk of skin irritation, rashes, and maceration by allowing excess moisture to evaporate, keeping the skin dry.

Regulated Body Temperature: In apparel and protective clothing, breathable filmed non-woven fabric helps regulate the wearer's body temperature. It allows excess heat and moisture to escape, preventing overheating and discomfort.

Filtration: Some applications require a balance between breathability and filtration. For example, in face masks and respirators, the breathable film layer may have specialized features to allow airflow while still providing effective filtration against airborne particles.

Hygiene Products: In disposable diapers and adult incontinence products, the breathable backsheet made of filmed non-woven fabric helps prevent diaper rash and keeps the wearer comfortable by allowing moisture vapor to pass through while blocking liquid leakage.

Medical Textiles: In the medical field, breathable filmed non-woven fabric is used in the construction of surgical drapes and gowns. These materials help maintain a sterile environment by preventing the passage of liquids and microbes while allowing the surgical team to remain comfortable.

Environmental Considerations: Some variations of breathable filmed non-woven fabric are designed to be eco-friendly and biodegradable, addressing environmental concerns.

Customization: Manufacturers can adjust the breathability of filmed non-woven fabric by modifying the design and structure of the breathable film layer. This allows for tailored solutions that meet the specific requirements of different applications.

In summary, the breathability of filmed non-woven fabric is a crucial characteristic that enables the controlled passage of air and moisture vapor while maintaining a barrier against liquids and contaminants. This feature enhances comfort, skin health, and overall performance in various applications across industries.

Filmed non-woven fabric

Filmed non-woven fabric

English

English Español

Español