Non-woven fabrics are non-woven fabrics made of fibers physically combined and widely used in medical, health, home, industry and other fields. Due to their different structures and manufacturing processes, non-woven fabrics are usually weak in waterproof performance. Non-woven fabrics themselves do not have complete waterproof capabilities, but their waterproofness is closely related to factors such as material, thickness and whether they have been specially treated.

Basic characteristics of non-woven fabrics

The main components of non-woven fabrics are natural or synthetic fibers, such as polypropylene (PP), polyester (PET), etc., and the fibers are usually combined by processes such as heat pressing, needle punching or chemical bonding. Unlike traditional woven fabrics, non-woven fabrics do not require the interweaving of warp and weft threads. Its production process is simple and low-cost, making it the preferred material for many industries.

Non-woven fabrics have the advantages of being light, breathable, soft and environmentally friendly, so they are widely used in products such as masks, medical dressings, surgical gowns, etc. in the medical and health field. In addition, it is also commonly used in disposables, filter materials, packaging materials and other fields. However, despite the many advantages of non-woven fabrics, its waterproofness is not ideal.

Waterproofness of non-woven fabrics

Non-woven fabrics usually have poor waterproof properties, mainly because there are large gaps between their fibers, and water can easily penetrate through these gaps. Therefore, untreated non-woven fabrics usually do not have waterproof functions. For some application scenarios that require waterproof properties, manufacturers often use some additional processes to improve the waterproofness of non-woven fabrics. For example:

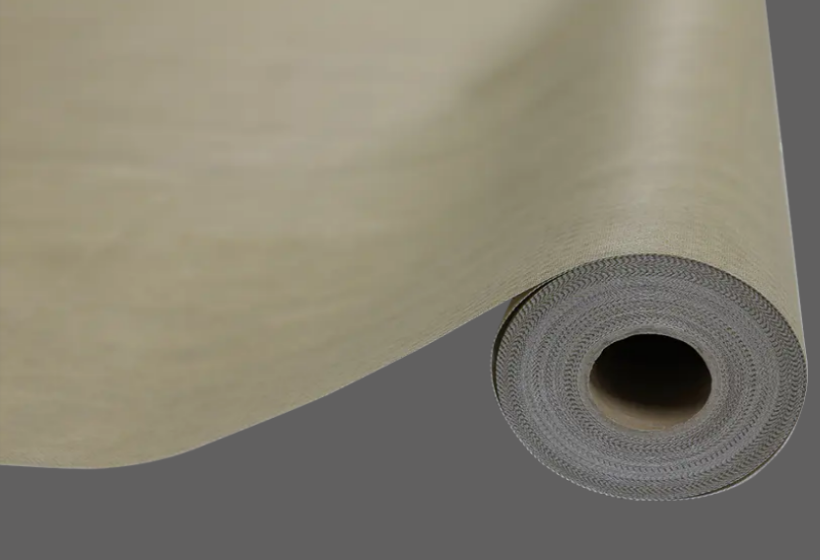

Coating treatment: Some non-woven fabrics will add a thin layer of waterproof coating, such as polyethylene (PE) coating, polyvinyl chloride (PVC) coating, etc., to improve waterproof performance. This type of non-woven fabric is suitable for packaging, coverings, etc. that require waterproofing.

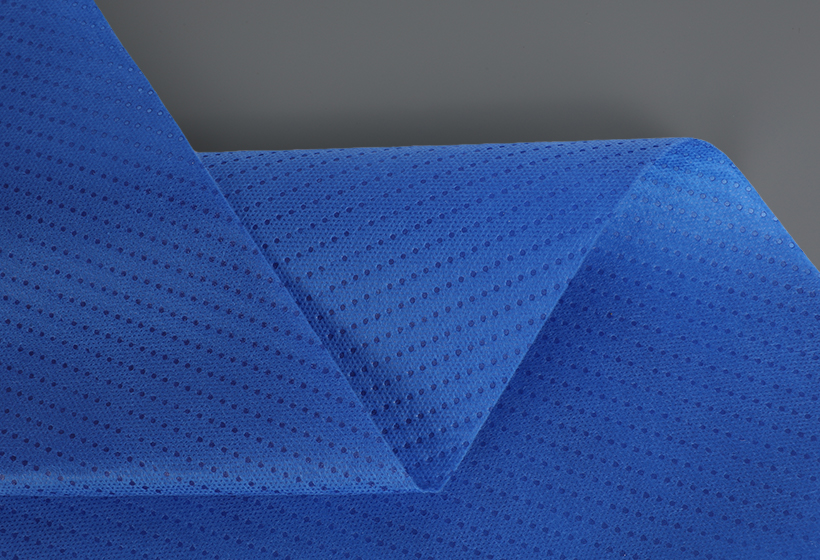

Composite materials: Another way to improve waterproofness is to form a composite non-woven fabric that is both breathable and effectively waterproof by combining it with other waterproof materials (such as films and membrane layers). This composite non-woven fabric is widely used in construction, outdoor products, and some high-demand waterproof occasions.

Special fiber materials: Using special fibers with waterproof properties (such as waterproof polyester) to make non-woven fabrics is also a way to improve their waterproof performance.

Application fields

Although non-woven fabrics have weak natural waterproof properties, modified non-woven fabrics perform well in many applications that require waterproofing. For example, waterproof non-woven fabrics are widely used in agricultural covering materials, building waterproof membranes, outdoor products (such as waterproof bags, raincoats), and other fields.

English

English Español

Español